| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Huayin

Model Number : HY-5Ton

Certification : CE ISO

Place of Origin : Xinxiang city, Henan,China

MOQ : 1 set

Price : USD38000-55000 per set

Payment Terms : L/C, T/T

Supply Ability : 220 sets per year

Delivery Time : 15-25 work days

Packaging Details : plastic flims for pyrolysis reactor , wooden boxes for small parts

Product name : No Pollution Plastic Waste To Oil Production Machine 5ton Plastic Pyrolysis Plant

Input raw material : waste plastic ,PP PE PS,ABS, pmma

Output product : Fuel oil , Carbon black ,gas

Heating fuel : Wood /Coal /Gas /Oil

Function : waste plastic pyrolysis machine

Rotating speed : 0.4 turn/minute

Opeartor : 3-4 workers

advantages : energy saving

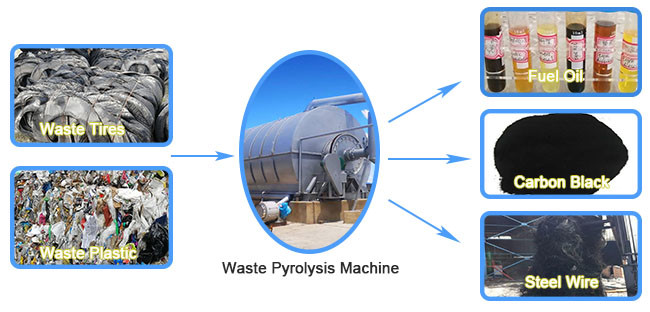

No Pollution Plastic Waste To Oil Production Machine 5ton Plastic Pyrolysis Plant

Product description

With the rapid development of the plastics industry, the application of plastic products is becoming more and more extensive, but because plastics are not easy to rot and degrade, this seriously affects the ecological environment of the earth. The waste plastic pyrolysis refining equipment is not only pollution-free to the environment, but also can recover energy effectively.

Input raw material

The applicable waste raw material includes various kinds of waste tires, car tires, bicycle tires, motorcycle tires, OTR tires, etc.

Various kinds of plastic waste, like PP, PE, PS, ABS, PMMA, etc.

Output product and usage

| Output Products | Application |

| Fuel Oil (50%-75%) | 1. Used as the heating material and sell it to cement factories, glass factories, ceramic factories, electric power factories, steel making factories, boiler factories, etc. 2. Used in heavy oil generator for electricity generation. 3. Deep process it into diesel oil with our distillation plant, color and smell removal system, the final oil can be used in diesel engines like trucks, tractors, etc. |

| Carbon Black (30%-35%) | Slag for construction. |

| Flammable Gas (8%-10%) | 1. Recycled into the furnace to heat reactor instead of coal/wood/oil/natural gas. 2. Storage the extra gas to restart the next batch. |

Specification

| Item | Content | |

| Raw materials | Waste tyre/rubber | |

| Output | 45% fuel oil, 30% carbon black, 10% steel wire, 10%-15% syngas | |

| Model | Reactor size | Capacity |

| HY1500*3000 | 1 T/batch | |

| HY2200*5500 | 5 T/batch | |

| HY2200*7500 | 7 T/batch | |

| HY2600*6600 | 8 T/batch | |

| HY2800*6000 | 9 T/batch | |

| HY2800*6600 | 10 T/batch | |

| HY2800*8000 | 15 T/batch | |

| Remarks | Support customization | |

| Reactor material and thickness | Q345R/Q245R/310S (Boiler plate/stainless steel) 16mm/18mm | |

| Land area | 300-400㎡ (L30-40m*W10m) | |

| Number of workers | 3-4 | |

| Oil density and calorific value | 0.89g/cm³&44.30KJ/KG | |

| Processing time and power | 10-24 hours. Averagely 15KW/h | |

| Certification | CE, ISO, BV, SUV, SGS Oil Report, Emission Report, 11 patents | |

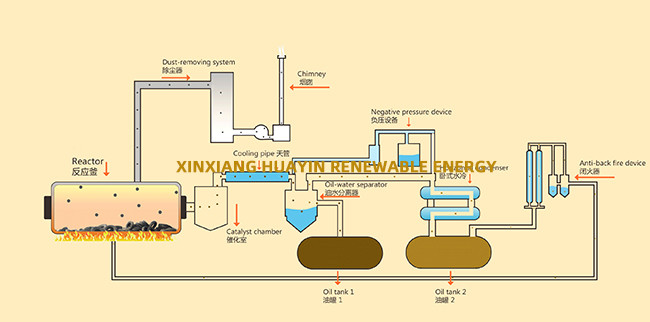

Operation Process

1: Feeding. Feed tires into reactor manually or with auto feeder;

2: Preheating. Waste tyres will be melted under high temperatures and oil gas comes out.

3: Oil-producing. Oil gas goes through the cooling system and is cooled down into liquid fuel oil; Some oil gas that can not be turned into liquid oil will go back to the heating furnace for second burning.

4: Cooling. After the oil processing is finished, leave the plant for cooling.

5: Carbon black discharging.

Our advantages

A. Safety. We treat safety as the first important thing in production.

1. Two devices to avoid backfire in production: oil-water separator and anti-back fire device.

2. Vacuum device makes the reactor work under ordinary pressure or negative pressure.

3. Temperature monitoring and Pressure gauge to monitor the pressure. If the pressure goes above a certain level, the bell will alarm and the safety valve will release the pressure automatically.

B. Environmental protection

Environmental protection

1. The flue gas (caused by burning fuel to heat the reactor) will be purified and cooled by a powerful ceramic packing dust removal device, then can be released into the air through the chimney.

2. Carbon black will be discharged out in sealed condition to avoid pollution.

C. Long service life

1. The material of the reactor is Q345R/Q245R boiler plate with 16/18mm thickness which is produced by a Chinese well-known enterprise. The head of the reactor and accessories are using one-piece molding shell cover rather than a welded plate.

2. The rollers are engineered underfeeding port and oil outlet port which are external to the heating area to bring perfect rotating balance and longer service life.

|

|

No Pollution Waste Plastic To Fuel Machine 5 Ton Plastic Pyrolysis Plant Images |